galileo escapement inventor drawing 3d printing

You bought your kickoff 3D printer and already printed the files that came with it as well every bit some of the complimentary 3D models bachelor on the spider web.

Even so, once you've done that information technology'south time to outset designing your own prints, only to do that you're going to accept to learn some 3D design.

So, in this article, I volition be giving you a full guide on how to start designing your own 3D models to print afterwards, what software to use, where to find courses for those 3D design software, and much more.

Then, without any further ado, let's get started!

- Design your Model using a CAD software

- Free CAD Software

- Tinkercad

- Fusion 360 Personal License

- FreeCAD

- Blender

- Paid CAD Alternatives

- Free 3D Blueprint Courses

- Some 3D modelling tips

- Pattern the parts with a flat base of operations

- Avoid Steep Overhangs

- Consider Layer Line direction (Stronger prints)

- Pay attending to size for dimensional accuracy

- Free CAD Software

- Slice the model using a Slicer

- Free Slicers

- Ultimaker Cura

- PrusaSlicer

- Premium Slicer Alternatives

- Save the Model to the SD carte du jour

- Utilize Octoprint as an alternative

- Free Slicers

- Conclusion

Pattern your Model using a CAD software

CAD software, or Computer Aided Design software, lets you build 3D models on a computer which can and so be 3D printed. Of course, these types of software are not simply practiced for designing your prints simply are also used for creating any kind of 3D element, be it for video games, animation, and more.

Once you're done press the free exam prints that come up with your printer, you generally download designs that other people fabricated (you can use our ain search engine to find amazing designs here). However, the ultimate challenge is to create them yourself using a CAD software, but this is definitely a lot harder to do than information technology may seem since 3D design tin can be quite circuitous.

In that location are some gratis CAD alternatives out there that are really uncomplicated to learn and apply as well equally some others that offer style more functionality at the cost of having a steeper learning curve. Of course, if yous want to learn how to create your own models via a course, and then check out this mail service I wrote about some of the best online 3D design & 3D Printing courses available (Free and also Paid).

Now, permit's check out some free CAD software!

Gratuitous CAD Software

I just want to note that Free software isn't necessarily worse than their premium counterparts. In fact, Fusion 360, which is the go-to design software used by most 3D printing enthusiasts, offers a complimentary license for personal employ with only a couple limitations. Even so, it'southward not the easiest CAD to learn.

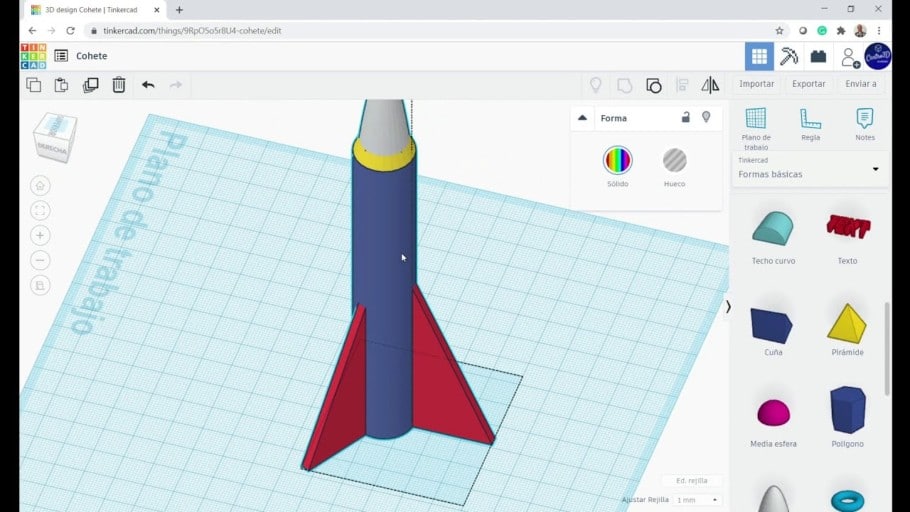

Tinkercad

Tinkercad (Link to Review) is a browser-based CAD that is 100% free and that is ideal for absolute beginners since it relies on a drag-and-drop interface where you can select different objects, such as squares, circles, etc., and use those to create the last pattern.

In improver to this, even though information technology's actually simple and straight forward to utilize, it'due south also a lot more powerful than information technology seems and will suit almost of your 3D design needs, plus every design yous create gets saved in the cloud and you can always access them from whatsoever device.

Check out Tinkercad here.

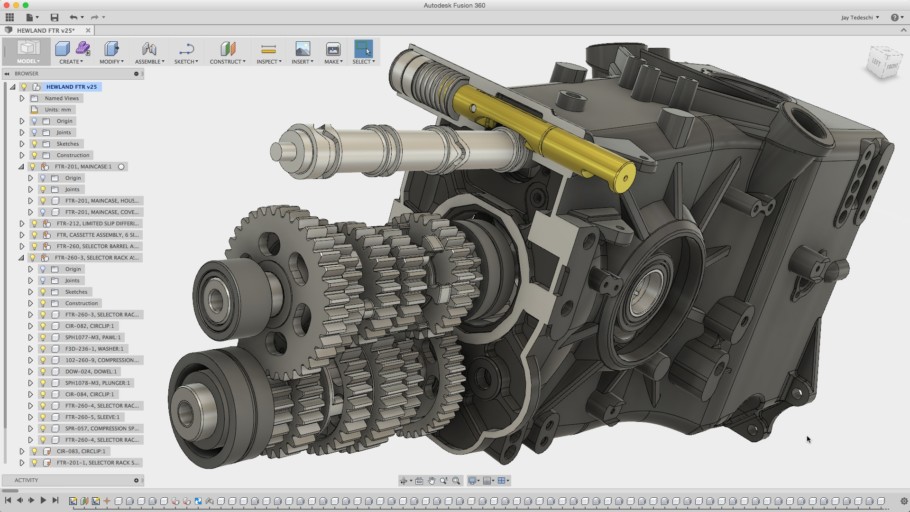

Fusion 360 Personal License

Fusion 360 (Link to Review) is probably the best-known CAD currently being used by 3D printing enthusiasts since it's extremely powerful and capable of creating every 3D model imaginable.

The learning bend is a lot steeper than the 1 of Tinkercad, but information technology's also a much more professional software capable of creating more complex designs.

Information technology offers a couple dissimilar pricing options and let me tell you, it'southward not a cheap software, merely they offer a personal license that you tin can use for free for three years and that only comes with some small limitations when compared to the premium version.

If you're a complete novice when it comes to 3D design, Fusion 360 might not be the friendliest CAD to go you started, but if yous follow some courses and if you take the time to learn information technology, y'all'll be able to create much better designs than with something like Tinkercad.

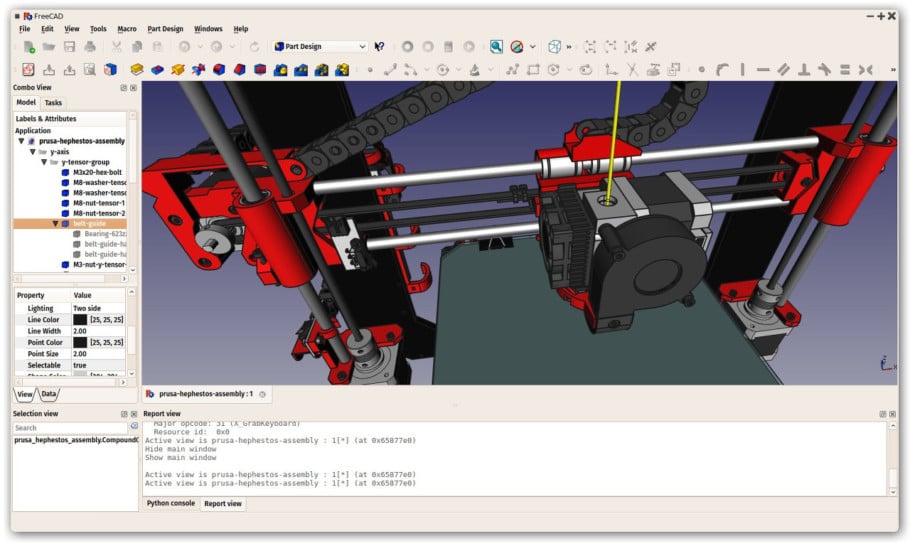

FreeCAD

FreeCAD (Link to Review) is a general-purpose and open-source 3D parametric blueprint software that has a wide range of uses. Its principal purpose is for designing mechanical engineering, electrical technology, and architectural objects.

For that reason, information technology is all-time used for geometric designs like accurate replacement parts, detailed technological parts, scale models, and edit gadgets.

FreeCAD (link to website) could exist considered a middle ground betwixt Fusion 360 and Tinkercad since information technology's a bit more powerful than Tinkercad while as well being more than beginner-friendly than Fusion 360, and at that place'south also loads of online resources bachelor where y'all can larn the ins and outs of FreeCAD to design your ain 3D models successfully.

Blender

Blender (link to review) is a 100% free 3D design software and it'southward the nearly used software for 3D printing when it comes to creating organic shapes. Otherwise, it is not the most practical software for designing precise and technical objects for which there are better-suited programs, like Fusion 360.

If you want to model organic shapes such every bit animals, humans, or monsters, Blender is one of the best options available simply considering of the fact that it is free, open-source, has powerful features, and a thriving community that is constantly improving the program.

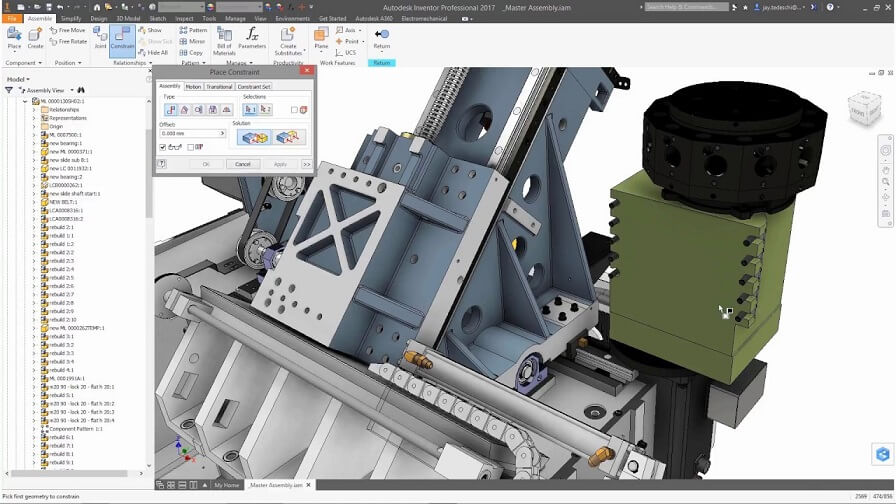

Paid CAD Alternatives

Virtually paid CADs are not aimed at hobbyist designers but rather professionals and corporations that employ this software for commercial purposes, which is why their licenses are usually very expensive and paid yearly.

For 99% of people reading this, none of these alternatives will be of much use to you since you tin definitely go by using Fusion 360's personal license and achieve astounding results with information technology.

Withal, some paid CADs include: AutoCAD, Fusion 360 (not the personal license i), Solidworks, Sketchup Pro, Solidedge, ZBrush, and many more.

Free 3D Pattern Courses

There are multiple free online 3D printing and Pattern courses available, but here are some of the ones I found to exist the about useful:

- Tinkercad Tutorial Series by Promo Ambitions.

- Fusion 360 for 3D Press 2022 by Austen Hartley.

- Foundations of Blender: Jewelry Design in 3D (By Gesa Pickbrenner).

These iii courses are all completely gratuitous and you lot have one for Tinkercad, one for Fusion 360, and another one for Blender, which should cover 99% of your needs.

Notation: The Skillshare courses are not free only you can sign up for the free trial that lasts a month and terminate all the courses you desire.

In the article I but linked, there are many more gratuitous courses as well as paid ones, but there's also plenty of YouTube tutorials out there that provide excellent information for each of those CADs.

Some 3D modelling tips

Here are some tips I thought of that should improve your chances of success while printing the models you designed, since there are some fairly common mistakes you lot can make that may end upwards ruining your print.

Blueprint the parts with a apartment base

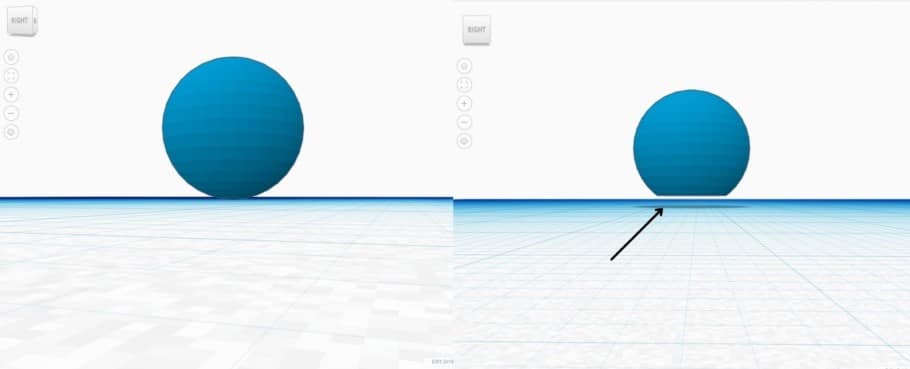

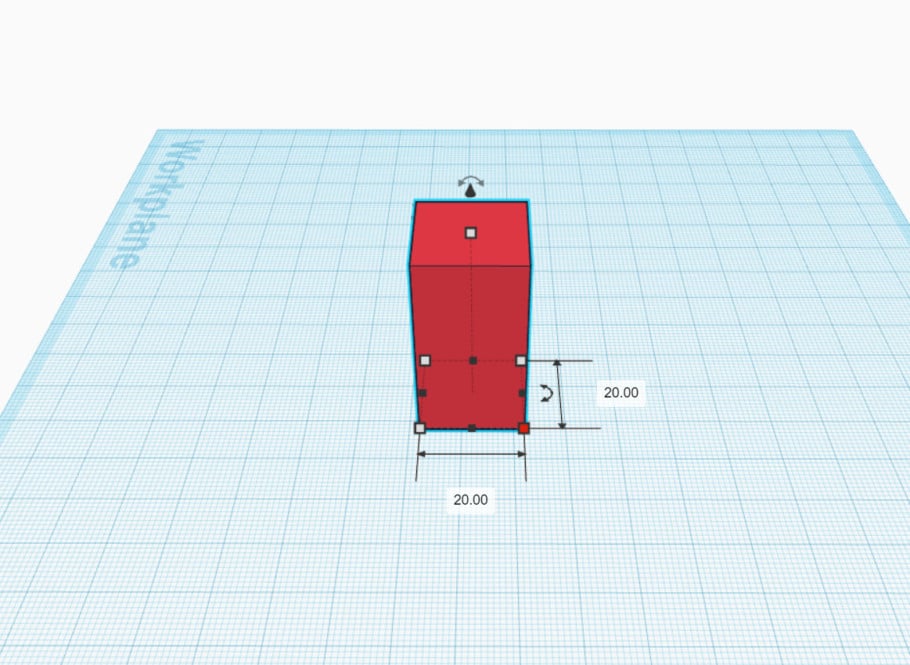

Right: Flat base, much better adhesion.

Probably the almost important factor when it comes to a successful print is achieving a good bed adhesion, which means that the surface of the model that's contacting with the bed should be as big as possible.

Imagine printing a round sphere where the bottom is rounded as well. In that example, there's not a lot of surface bachelor to reach a good bed adhesion, which means that the print will disassemble from the bed and the printer will continue printing in mid-air, leaving plastic strings all over the print surface.

Still, if you change the shape of the bottom of the model so that it'south completely flat, and if possible likewise with a big surface expanse, so bed adhesion volition be much meliorate and your prints success charge per unit will be much higher.

Avoid Steep Overhangs

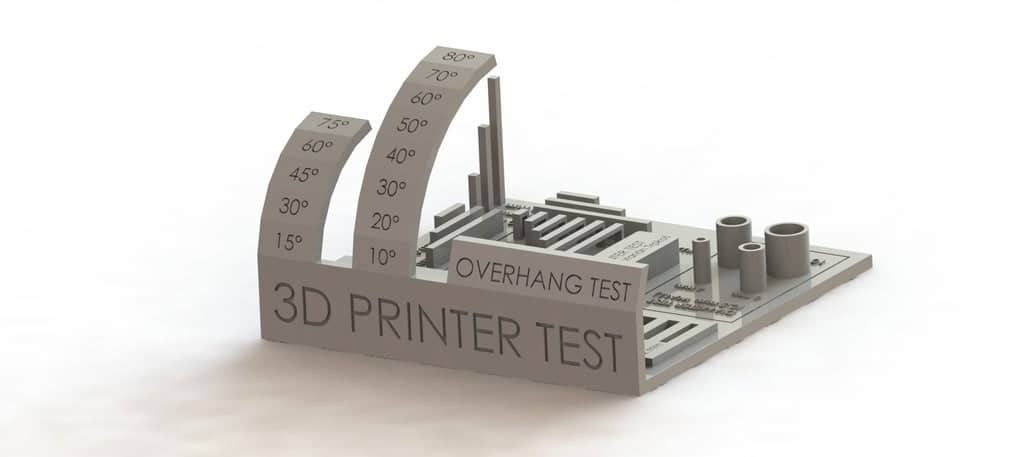

3D printing is done layer by layer from the ground upwards and the printer can impress at an angle without whatsoever issues or loss in printing quality as long equally that overhang bending isn't too steep.

If you look at the image beneath, you'll come across that it has an angled overhang on the left, a bridge overhang in the middle, and a cantilever overhang on the right. This is an object designed to show you what types of overhangs your printer can bargain with also as which ones information technology tin can't.

The angled and bridged overhangs (left and middle) are no problem for the printer since in that location's enough support textile available to keep the print from failing. Just the right overhang, since the printer would demand to impress in mid-air, will fail since there'south no back up structure for the filament to grab onto.

To circumvent this issue, yous should either impress using overhangs of no more than than 45° or include supports (a setting that is enabled in the slicer) since these will course a support structure under any overhang higher up a specific bending to continue information technology from failing.

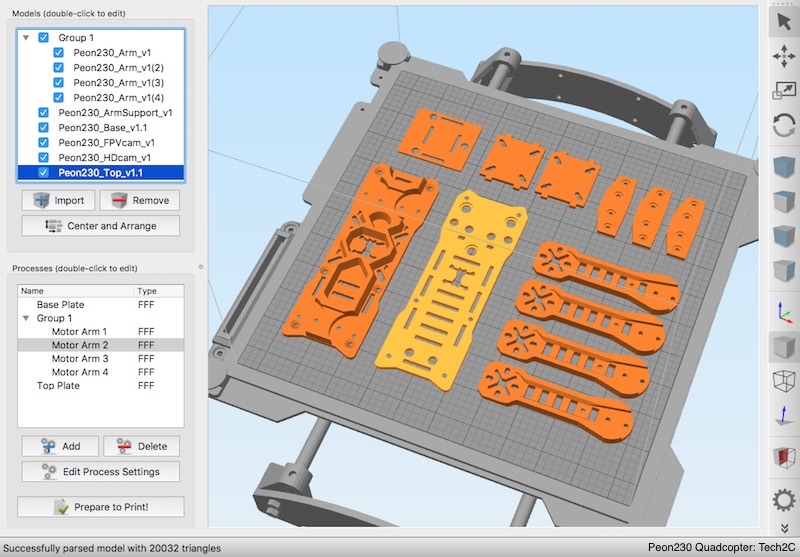

Consider Layer Line direction (Stronger prints)

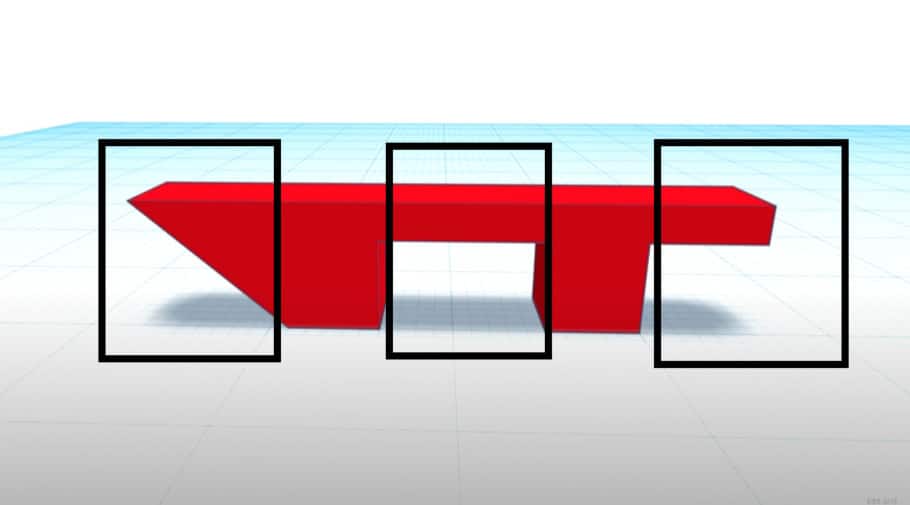

Since FDM 3D printing is done in layers from the ground up, nosotros can adapt the position of the model in the slicer before printing information technology to make it stronger.

Right: Horizontal layer lines.

This works because layer lines are very potent but the adhesion between those layers isn't. So, if you look at the epitome above where I sliced the exact same model but one gets printed vertically and the other i horizontally, the one with horizontal layer lines won't withstand every bit much of a pulling force while the 1 with the vertical layer lines will be much stronger.

You should always suit the position of the model in the slicer then that the layer lines are parallel to the force that the object is going to be subjected to and not perpendicular, this manner yous aren't relying on the strength of layer adhesion as much.

Pay attention to size for dimensional accurateness

When first starting out you'll probably design something that needs to be functional and fit tightly with another object, only to find that the dimensions you lot set were completely off.

In Tinkercad, too as every other CAD, you can meet the grid (generally in millimeters) which gives you a visual cue of how large the model is going to be. But y'all can besides click on the model and adjust the length, width and height easily by typing it in.

Always make sure to use calipers to take the right measurements and enter those into your CAD to exist equally precise as possible.

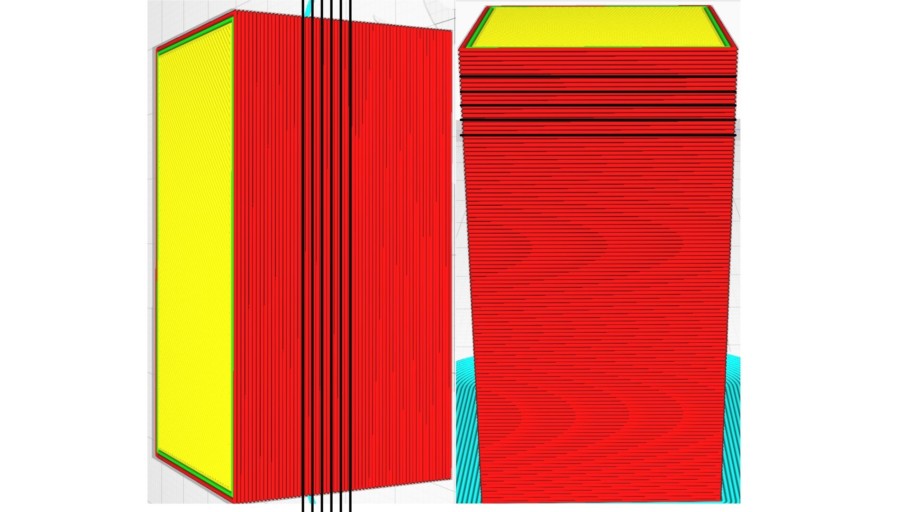

Slice the model using a Slicer

FDM 3D printing works in layers: The printer starts from the very bottom, prints an unabridged layer and and so moves up to the next i, etc. until the printing process is complete. Slicers essentially "slice" the model up in unlike layers from the bottom upward and create a gcode file which contains all the information the printer needs in order to print the object.

Luckily, all free Slicer currently bachelor are absolutely fantastic and piece of work really well, and in that location's rarely a case where going with a premium Slicer makes any sense nowadays.

Hither's a list of the best free Slicers:

Free Slicers

In that location's probably a dozen different free Slicers out there, nonetheless, I'k only going to list two since I think that those will embrace all your needs!

Permit's start with the one I use, Cura.

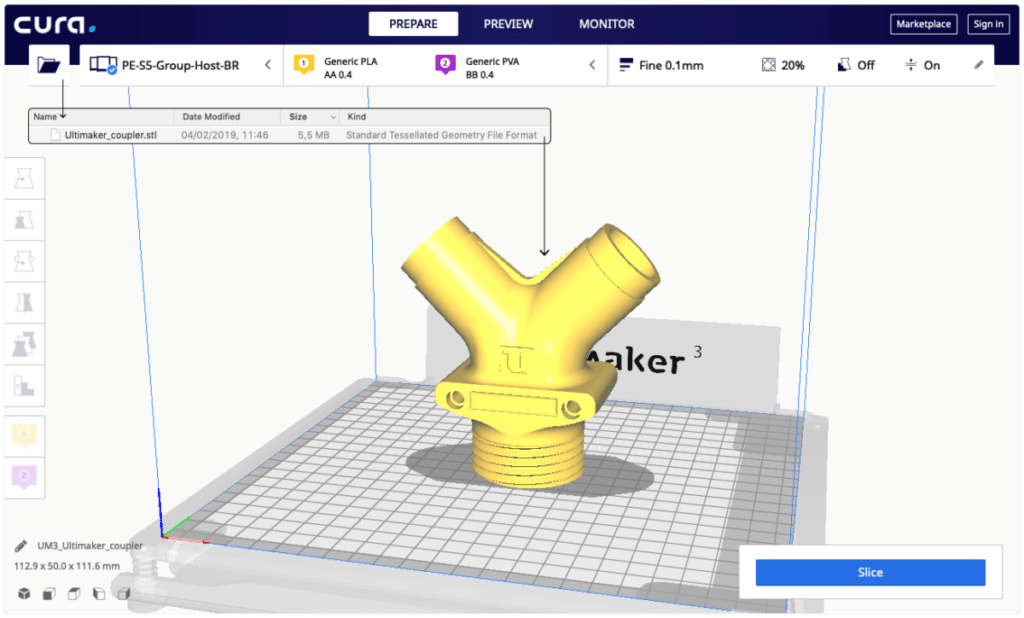

Ultimaker Cura

Cura is the about-used Slicer out there but because it works, it's intuitive, it gets consistent updates, and it also characteristic a huge number of gratis plugins that you tin can install and which will brand your life a lot easier.

For example: If y'all are trying to notice a mode of positioning the model to exist sliced so that information technology uses the least amount of support textile possible, well Cura has got yous covered.

Definitely check Cura out, it's a great software.

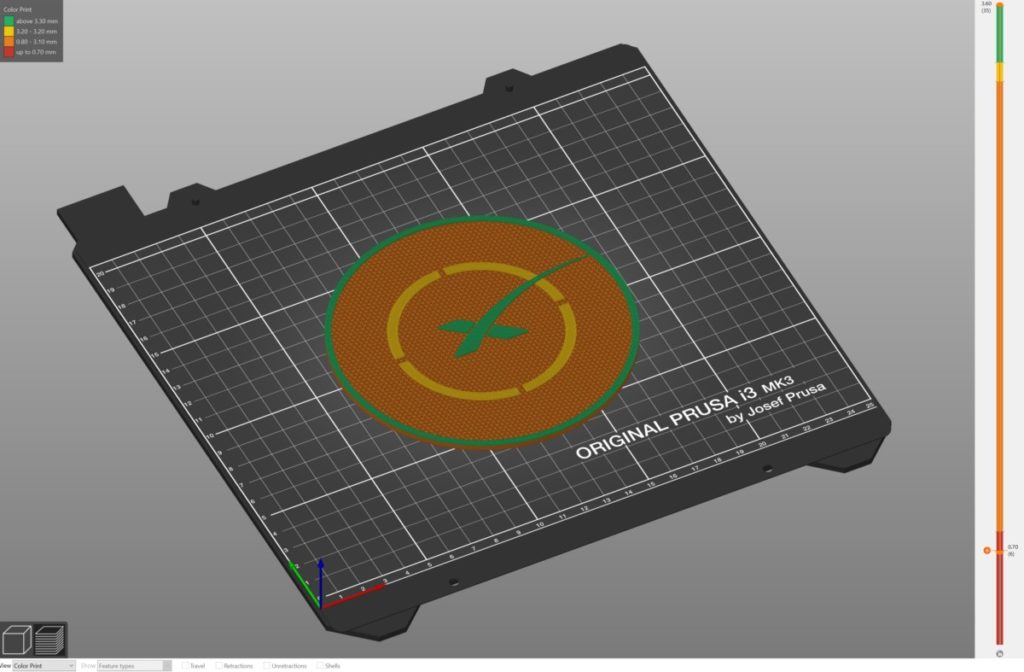

PrusaSlicer

PrusaSlicer, contrary to Cura, not only works with FDM printers but likewise SLA (resin printers), which makes information technology extremely versatile.

However, it doesn't come with any free plugins that you can install, but information technology does offer span detection and "if-statements", plus it's also getting updated regularly, meaning that it's just going to get better over time.

Premium Slicer Alternatives

I already mentioned that I don't think that about people will e'er demand to pay for a premium slicer, particularly considering how fast all the free ones are improving.

However, going with something similar Simplify3D may make sense if you're running a 3D printing shop, only I generally recommend going with the free alternatives.

Save the Model to the SD card

This is a very like shooting fish in a barrel and straightforward step, but you demand to practice information technology in order to go the information over to the printer if you want to be able to print the model.

Cura automatically lets y'all save the file to the removable bulldoze and even ejects it for you, but depending on the slicer you might have to practise this manually. Brand sure to always name the file appropriately so that yous know what file y'all're selecting from the printer.

All the same, if you're running a printing farm or if you want to control the printer remotely, and then in that location's a more efficient way of doing things.

Utilize Octoprint as an alternative

OctoPrint is a web interface for your 3D printer that allows you to control and monitor all aspects of your printer and print jobs right from your within your browser.

You tin can access a webcam feed to make sure the print is moving forward as expected, as well as being able to take a look at temperatures, view reports on the progress of the prints, command the printer itself, create a printing queue, analyze the bed level via the bed level visualizer, and more.

Decision

Creating 3D models that tin can be printed on your 3D printer is a adequately simple procedure, with the hardest part beingness designing the actual model itself.

I'd recommend starting with Tinkercad since it's extremely intuitive and easy to use, and every bit long equally you don't need to create really complex models don't upgrade to Fusion 360 since it will have you a lot longer to learn the software.

The rest of the process is extremely unproblematic, actually, so I'd mainly worry about learning 3D design.

I promise this was useful!

Have a cracking twenty-four hours!

Source: https://3dsolved.com/create-models-for-3d-printing/

Belum ada Komentar untuk "galileo escapement inventor drawing 3d printing"

Posting Komentar